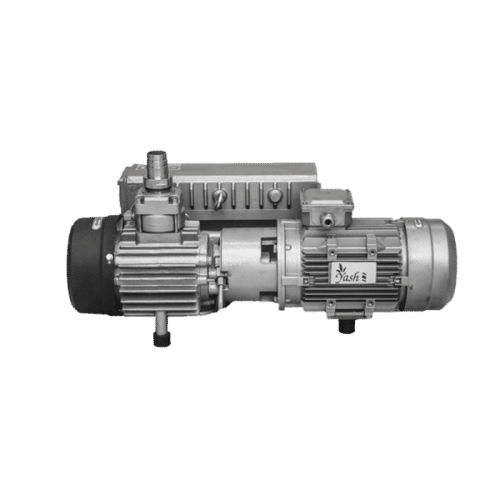

CX Series Centrifugal Air Blower

11500.0 आईएनआर/Unit

उत्पाद विवरण:

- रंग चाँदी

- उपयोग Industrial

- प्रॉडक्ट टाइप CX Series Centrifugal Air Blower

- साइज Standard

- मटेरियल अल्युमीनियम

- पावर

- एप्लीकेशन

- Click to view more

X

सीएक्स सीरीज़ सेंट्रीफ्यूगल एयर ब्लोअर मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 1

सीएक्स सीरीज़ सेंट्रीफ्यूगल एयर ब्लोअर उत्पाद की विशेषताएं

- चाँदी

- अल्युमीनियम

- Industrial

- Standard

- CX Series Centrifugal Air Blower

सीएक्स सीरीज़ सेंट्रीफ्यूगल एयर ब्लोअर व्यापार सूचना

- 100 प्रति दिन

- 7 दिन

उत्पाद विवरण

CX Series Centrifugal Air Blower offered by us is a centrifugal turbo blower. Offered is serviceable as a durable unit that can work with film production machines, printing machines, toxic waste apparatus, hot air blowers, incinerators, uniform hotness apparatus, burning machines, synthetic extruders, food and beverage industries, domestic machines, grain elevators, dust collectors, textile equipment, dryer equipment, cooling machines, etc. This blower is capable to make high pressure and is offered with supreme flow rate. The air flow can be accordingly adjusted to the different designs.

Centrifugal Air Blower Features:

1. Makes use of advanced centrifugal engineering technology.

2. Offered with increased reliability as well as negligible maintenance.

3. Ergonomically designed, boasts of an optimum plug-and-play operation. Offers flawless operation in many job site conditions.

Centrifugal Air Blower Applications:

1. HVAC Systems: Centrifugal blowers are widely used in heating, ventilation, and air conditioning systems for commercial buildings, offices, hospitals, and industrial facilities. They help in circulating air, maintaining indoor air quality, and regulating temperature.

2. Industrial Ventilation: In industrial settings such as manufacturing plants, warehouses, and workshops, centrifugal blowers are utilized for ventilation purposes to remove fumes, dust, and other airborne contaminants, ensuring a safe and healthy working environment.

3. Pneumatic Conveying Systems: Centrifugal blowers are essential components in pneumatic conveying systems used in industries like food processing, pharmaceuticals, and mining. They facilitate the transportation of bulk materials such as grains, powders, and granules through pipelines or ducts.

4. Air Pollution Control: In pollution control systems, centrifugal blowers are employed to exhaust harmful gases, particulates, and odors from industrial processes, helping to comply with environmental regulations and maintain air quality standards.

5. Wastewater Treatment: Centrifugal blowers are used in wastewater treatment plants for aeration purposes. They provide oxygen to biological treatment processes like activated sludge systems, aiding in the breakdown of organic matter and pollutants in sewage.

6. Drying and Cooling Systems: Industries involved in food processing, paper manufacturing, and textiles utilize centrifugal blowers in drying and cooling processes. They help in removing moisture from products or materials and maintaining optimal operating conditions.

7. Power Generation: Centrifugal blowers are employed in power plants for combustion air supply to boilers and furnaces. They ensure efficient combustion by delivering the required amount of air at the correct pressure to support the combustion process.

8. Agricultural Applications: In agriculture, centrifugal blowers are used for grain drying, ventilation in livestock buildings, and dust collection in grain handling facilities. They help in maintaining suitable conditions for crop storage and animal welfare.

9. Air Handling Units (AHUs): Centrifugal blowers are integral components of AHUs used in commercial and residential buildings. They assist in circulating conditioned air throughout the building and regulating indoor air quality and temperature.

10. Vacuum Systems: In vacuum applications such as material handling, packaging, and medical suction devices, centrifugal blowers are utilized to create suction or negative pressure for various processes.

Centrifugal Air Blower Advantages:

1. High Efficiency: Centrifugal blowers are known for their high efficiency in moving air. They can generate a significant airflow while consuming relatively low power, resulting in energy savings and lower operating costs.

2. Variable Speed Control: Centrifugal blowers can easily be controlled to adjust the airflow and pressure according to specific requirements. Variable speed drives allow for precise modulation of the blower speed, providing flexibility in various applications and improving overall system efficiency.

3. Wide Range of Pressures and Airflows: Centrifugal blowers can operate across a wide range of pressures and airflows, making them suitable for diverse applications. They can deliver high-pressure air for pneumatic conveying or low-pressure air for ventilation and cooling systems.

4. Compact Design: Centrifugal blowers typically have a compact and space-saving design compared to other types of blowers. This makes them suitable for installations where space is limited or where a smaller footprint is desired.

5. Quiet Operation: Centrifugal blowers tend to operate more quietly than other types of blowers, especially at lower speeds. This makes them suitable for applications where noise levels need to be minimized, such as HVAC systems in residential or commercial buildings.

6. Durable and Reliable: Centrifugal blowers are generally robust and durable, with fewer moving parts compared to positive displacement blowers. This results in lower maintenance requirements and improved reliability, reducing downtime and maintenance costs.

7. Suitable for High Temperatures: Centrifugal blowers can handle higher temperatures compared to axial fans, making them suitable for applications involving hot air or gases. They are commonly used in industrial processes such as drying, heat treating, and combustion air supply.

8. Cleaner Air Handling: Centrifugal blowers are capable of handling clean or dirty air streams efficiently. They can be equipped with filters or other air treatment devices to ensure the delivery of clean air in various applications, including air pollution control and HVAC systems.

9. Adaptable to Various Environments: Centrifugal blowers can be constructed from a variety of materials, including stainless steel, aluminum, and plastics, to suit different environmental conditions and applications. This versatility makes them suitable for use in corrosive or hazardous environments.

Centrifugal Air Blower FAQ:

1. How does a centrifugal air blower work?

When the impeller of a centrifugal blower rotates, it draws air into the inlet and accelerates it radially outward. This action increases the air's velocity and pressure before it exits through the outlet. The airflow is perpendicular to the impeller's rotation axis.

2. What are the main components of a centrifugal air blower?

The main components of a centrifugal blower include the impeller, housing or casing, inlet and outlet ducts, bearings, drive motor, and sometimes, additional features like dampers, filters, and noise attenuators.

3. What are the types of centrifugal air blowers?

Centrifugal blowers can be classified based on their design and construction, including radial, forward-curved, backward-inclined, and airfoil types. Each type has unique characteristics and performance capabilities suited for specific applications.

4. What are the typical applications of centrifugal air blowers?

Centrifugal blowers are used in various industries and settings for applications such as HVAC systems, industrial ventilation, pneumatic conveying, air pollution control, wastewater treatment, drying and cooling processes, power generation, and agricultural operations.

5. How do I select the right centrifugal air blower for my application?

Choosing the right centrifugal blower involves considering factors such as airflow requirements, pressure conditions, temperature, material compatibility, space limitations, and system efficiency. Consulting with a knowledgeable supplier or engineer can help in selecting the most suitable blower for your specific needs.

6. What maintenance is required for centrifugal air blowers?

Maintenance tasks for centrifugal blowers typically include regular inspection of bearings, lubrication, cleaning of the impeller and housing, checking for wear and tear, and ensuring proper alignment and balance. It's essential to follow manufacturer recommendations and schedule routine maintenance to ensure optimal performance and longevity.

7. Can centrifugal air blowers be used for both clean and dirty air applications?

Yes, centrifugal blowers can handle both clean and dirty air streams effectively. Depending on the application, they can be equipped with filters, screens, or other air treatment devices to ensure the delivery of clean air and protect the blower from contaminants.

8. Are centrifugal air blowers noisy?

While centrifugal blowers tend to operate more quietly than some other types of blowers, noise levels can vary depending on factors such as blower size, speed, design, and installation. Noise can be mitigated through proper design, installation, and the use of noise reduction features like silencers or enclosures.

9. Can centrifugal air blowers be used in hazardous environments?

Yes, centrifugal blowers can be designed and constructed to meet the requirements of hazardous environments where flammable gases, vapors, or dust are present. Special considerations such as material selection, motor enclosures, and explosion-proof features may be necessary to ensure safety and compliance with regulations.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese